Is your concrete sinking into the ground? If so, then it’s likely that the slab was installed on dirt that was not compacted properly. Other possibilities are sub-surface erosion and shrinking soils. If you are lucky enough to have a local slabjacking business in your area then the concrete should be able to be repaired instead of replaced. Slabjackers can raise the sunken concrete slab to its original position. This is done by mixing cement, sand, fly ash, and other additives and pumping the mixture below the slab.

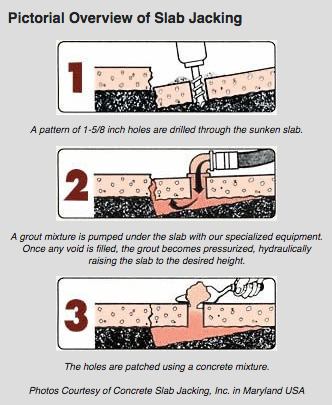

First, a series of holes are drilled through the sunken slab, the holes are usually about 1 ½ to 2 inches in diameter. Then the grout mixture is pumped under the sunken slab with low pressure using a special nozzle and hose that fits into the holes. After the grout fills all of the void areas it becomes pressurized raising the slab back to the original height. After the slab is at the desired height the holes are filled with a stiff mortar mix to make a clean finish. Usually it costs less to slabjack a driveway than it does to replace it. (Click here for more information on slabjacking steps.)

So why does concrete sink to begin with? Almost always, fill dirt is put along the side of the house and garage foundations after the foundation work is complete. Doing so allows the voids to be filled during the foundation constructing process. More often than not, the builder does not take the time to adequately compact this dirt. The soils are made up of solid particles and the voids between the particles. The void spaces can spell trouble for structures and concrete slabs due to the weight of the structures literally squeezing any air and water from the soil below. When this happens the soil will sink and the slabs or structures will follow.

These problems can actually usually be avoided completely if using a granular fill like sand or a sand and gravel mix rather than using fill dirt. Granular fill can be compacted easily using a hand held vibratory compactor. A granular fill should also be used to fill in trenches that cross driveways and sidewalks. Properly compacting the fill will prevent air voids, which are the reason concrete slabs crack and sink.

Some of the benefits of slabjacking are:

- The mixture pumped below the slab provides a strong base, so it can be injected in virtually any weather conditions.

-The landscaping typically does not need to be disrupted.

-Typically, you don’t need to move items off of the slab when injecting the mixture. The pump will be able to lift the weight of the slab and any items on it.

-The cost is low, the average cost of slabjacking concrete is ⅓ the cost of replacement.

-There is little mess or inconvenience due to the slabs not actually being removed.

-The slab can be used immediately after slabjacking as opposed to having to wait 28 days for concrete to cure for full strength.

-There is no waste, as opposed to replacing the slab which results in waste.

-There is no loud concrete breaking, which causes dust and debris.

-The color of the concrete doesn’t change due to not having to replace the slabs with new concrete.

There are so many creative and custom options for finishing concrete, but first and foremost important is the concrete itself. At Custom Concrete Creations we have state of the art equipment and a properly trained team with years of experience. Custom Concrete Creations is a premier contractor serving the Omaha area as well at the Midwest. Give us a call or send us an email for your custom concrete finishing needs today!

![]()